5:03 AM

1. TITLE Method Statement for the Installation of Kerbstone. 2. SCOPE OF WORKS 2.1 General Description · The scope ...

Method Statement for Kerbstone Installation

1. TITLE

Method Statement for the Installation of Kerbstone.

2. SCOPE OF WORKS

2.1

General Description

·

The

scope and purpose of this method statement is to outline the general

requirements and precautionary measures which should be taken into

consideration during installation of kerbstone and to ensure that works are

according to the drawings, standards and project specification.

2.2 Plant

and Equipment

2.2.1

Trowel

2.2.2

Masons Rubber Hammer

2.2.3

Masonry power saw

2.2.4

Level bar

2.2.5

Mason’s line

2.2.6

Steel square

2.2.7

Brushes

2.2.8

Shovels

2.2.9

Powered mortar mixer

2.2.10

Kerbstone clamp

2.2.11

Skid stud loader

2.3

Materials

S.N

|

Material

|

Status

|

|

1

|

Kerbstones

|

reference transmittal

|

approved or rejected

|

2.4 Site

Planning and Preparation

2.4.1

Prior to

installation, all areas for kerb laying shall be properly marked by surveyor as

per approved drawings.

2.4.2

Proper planning

of execution as per area of installation shall be made.

2.4.3

All required materials

shall be placed near on site of installation with quantity as per site

requirements.

2.4.4

Material

transfer shall be through tower crane lifting to the nearest point from the

place of installation.

2.4.5

Horizontal

transfer of materials shall be made by using push cart.

2.5.1 Documentation

1. Ensure that all materials, sample, accessories and method of statement are approved prior to execution on site.

1. Ensure that all materials, sample, accessories and method of statement are approved prior to execution on site.

2. Prior

to execution of works, an execution clearance shall be obtained from MEP for

proper coordination regarding cut out.

2.5.2

Material

Specification:

All materials and accessories to be used shall

be as per material approval.

2.5.3

Installation

2.5.2.1

Surface of installation shall be properly marked by surveyor as per

approved drawings. Top Level of the kerb shall be 275 cm from slab level.

2.5.2.2

All marking shall be done by Surveyor as per the approved shop drawing

prior to any installation of kerbstone.

2.5.2.3

Kerb Stone shall be laid

spaced 6 mm on joints onto sand/cement (3:1) mortar bedding 25 mm thick with a

continues concrete backing support with dowel bars fixed by anchoring epoxy

resin. (see illustration below)

2.5.2.4

Joints shall be filled

with fluid sand cement mortar.

2.5.2.5 No pavement or

any materials shall be placed on the kerb until such backing is completely

dried.

2.5.2.6 Kerb shall be

properly cleaned after installation.

2.5.2.7 Kerbs shall have

3mm tolerance at each end of an element, to the designated lines and grades.

0 Comments

4:49 AM

1. TITLE Method Statement for Carpet Installation 2. SCOPE OF WORKS 2.1 General Description · The scope and purpo...

Method Statement for Carpet Installation

1. TITLE

Method Statement for Carpet Installation

2. SCOPE OF WORKS

2.1

General Description

·

The

scope and purpose of this method statement is to outline the general

requirements and precautionary measures in Carpets Installation. This

should ensure that the works will be done with good quality as per the project

specification, standards and drawings.

2.2

Plant and Equipment

·

Cutter / Scissor

·

Scraper

·

Meter Tape

·

Straight Edge

·

Framing Square

·

Paint Roller

2.3

Materials

S.N

|

Material

|

Status

|

|

1

|

Approved Carpet model and type

|

reference submittal

|

approved or rejected

|

2

|

Accessories

|

||

2.4.1 Handling and Storage

·

The materials delivered at site shall be

carefully off-loaded as per manufacturer’s instructions by deploying

necessary/adequate manpower in such a way that no damage is caused.

·

Materials that

cannot be offloaded from delivery vehicles and transported to the working areas

by hand may be handled by suitable equipment such as trolleys pallet truck and

furniture skate.

·

All the

materials shall be handled and stored properly at allocated location at site.

·

It shall be

ensured that the delivered materials are in compliance with the approved

material submittal.

·

All minor

components supplied shall be identified and sorted properly.

·

The materials

shall be stored carefully to avoid any damages due to the construction

activities in a place as per manufacturer’s recommendation.

·

Any

discrepancies, damages etc. found shall be notified and reported to the

Engineers for further action & notification shall be sent to supplier.

·

Material found

not suitable for site use shall be removed from site immediately and replaced

with new suitable material.

2.4.2 Surface

or Substrate Preparation

·

Comply with

carpet tiles manufacturer’s recommendation for preparing substrate indicated to

receive Carpet tiles.

·

After casting of

required thickness of screed and as per the design requirements, surface to be

smooth, straight to finish and suitable to execute the work.

·

Repair all

cracks, holes and depression in substrates.

·

Remove all

substances incompatible with the flooring adhesive and that contain soap,

grease/oil, wax and silicone as per manufacturer’s recommendation.

·

Broom and vacuum

clean substrate to be covered immediately before product installation. After

cleaning examine substrate for moisture, alkalinity salts, carbonation or dust.

Do not proceed with installation until satisfactory conditions have been

corrected.

2.4.2 Installation

Procedure

·

Installation

procedure will be as per manufacturer’s recommendation.

·

Prior to start

of installation activities, refer to the approved shop drawings related to the

installation area & ensure that carpet flooring shall be as per approved

material submittal. MEP clearance for any utilities shall be secured prior to

start the succeeding works. Execution Clearance shall be signed and approved by

all parties prior to installation of carpet to ensure no other work balance of

the screed.

·

Ensure that

approved shop drawing related to the installation area & materials are as

per approved material submittal.

·

Begin the layout by carefully marking working lines

on the floor surface to act as the starting position and guide for your carpet

tile installation. First, determine that your room is as square as possible:

Take measurements to determine the center of the room and snap a horizontal and

a vertical chalk line that intersect at the center of the room. (see Figure-1)

·

The adhesive must be applied in a full spread rate

as per manufacturer’s recommendation.

·

Allow the adhesive to dry to a clear tacky state.

·

Once the adhesive properly sets up place the first

four tiles carefully along the intersection of your first quadrant, stair

stepping each tile as you go (see Fig. 2).

Figure – 2

·

Once the adhesive properly sets up place the first

four tiles carefully along the intersection of your first quadrant, stair

stepping each tile as you go (see Fig. 2).

·

This pyramid technique keeps the entire layout

square and in reference to the chalk lines. Slide each tile into position from

the side to prevent trapping yarn. Trapped yarn will affect the appearance of

the installation and cause alignment problems. Do not compress tile when

installing, this will cause peaking, requiring reinstallation.

·

Use a framing square / square angle to randomly

check squareness of installation (see Fig. 3).

Figure – 3

·

Carpet tiles cut well from the

back. Tiles should be cut so that the trimmed edge will always be placed

against the wall. After Installation, all areas must be rolled with a seam

roller to blend and enhance seams.

NOTE: Compressing the tie at the wall

can cause edge peaking.

|

Tile

|

|

Straightedge

|

|

|

|

Floor

|

Figure - 4

·

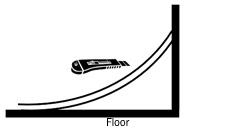

Figure 4. One method of trimming the tiles is to

measure the distance between the wall and the closest installed full tile.

Utilizing the measurement, mark the back of the tile to be trimmed with a

pencil or pen and a straight edge or other straight object. Using a sharp

blade, score the tile along the marked line and bend or break the tile. Sever

the tile along the line using a sharp blade.

·

When trimming around doors and columns, rigid

“utility type” blades often work better than more flexible slotted blades.

Carpet Tiles are easiest cut by scoring the back with a rigid blade, and then

bending or breaking the tile. The tile can then be severed with a sharp blade.

·

Figure 5. If preferred, Carpet Tiles can be trimmed

by coving the tile up the wall, and trimming free hand. Wall trimmer work best

for this type of trimming. Rigid Hook or straight blades also work well.

·

Chair pads are recommended under office chairs with

roller casters to preserve appearance retention, avoid premature and

accelerated wear.

·

After completion of each work the area shall be kept

clean and closed to avoid dirt on the carpet.

·

After the installation until being taken to use the

carpets should be protected against damage and soiling from traffic and

subsequent craftsmen. The extent and type of covering will depend on the type

of load, traffic intensity and weather a dry or wet load can be expected.

·

No furniture or equipment should be placed on the

carpet before the floor adhesive is completely dry and tempered which can take

up to 24 hrs.

·

Working areas will be kept clean by disposing the

waste materials at the designated work areas.

0 Comments

Subscribe to:

Comments (Atom)

Popular Posts

Recent Posts

Popular Posts

-

1. TITLE Method Statement for repairing of tie rod hole. 2. SCOPE OF WORKS 2.1 General Description · The scope an...

-

1. TITLE Method Statement for the Backfiling Works. 2. SCOPE OF WORKS 2.1 General Description · The scope and pur...

-

1. TITLE Method Statement for the Concreting Works of Raft Foundation . 2. SCOPE OF WORKS 2.1 General Description · ...

-

1. TITLE Method Statement for the Installation of Kerbstone. 2. SCOPE OF WORKS 2.1 General Description · The scope ...

-

TABLE OF CONTENTS 1.0 Objectives 2.0 Scope 3.0 Reference 4.0 Abbreviations 5.0 Health and Safety 6.0 Equipments 7.0 Responsibilitie...

-

1. TITLE Method Statement for Carpet Installation 2. SCOPE OF WORKS 2.1 General Description · The scope and purpo...

-

1. TITLE Method Statement for Concrete Crack Repair 2. SCOPE OF WORKS 2.1 General Description · The scope and pur...

-

1. TITLE Method Statement for Installation of Wall and Floor Tiles 2. SCOPE OF WORKS 2.1 General Description ...

-

1. TITLE Method Statement for Plastering Works. 2. SCOPE OF WORKS 2.1 General Description The scope and purpose of this me...

-

1. TITLE Method Statement for Painting Works of wall and ceiling 2. SCOPE OF WORKS 2.1 General Description The scope and pur...

.png)